Product overview

ZWL type direct-connected self-priming non-clogging sewage pump is a novel self-priming pump product developed successfully on the basis of repeated research on similar technologies at home and abroad. The pump set self-priming and non-clogging sewage in one, the use of axial return external mixing, and through the pump body, impeller flow channel design, can be like the general self-priming clean pump does not need to install the bottom valve and irrigation water, but also can suck and drain containing large particles solid and long fiber impurities liquid, It can be widely used in municipal sewage engineering, river pond culture, light industry, paper making, textile, food, chemical, electrical, fiber, slurry and mixed suspension and other chemical media ideal impurity pump.

The blowdown self-priming pump adopts the direct connection structure, has the characteristics of simple and compact structure, less vibration, good self-priming performance, strong blowdown capacity, convenient use and maintenance, etc. It has a broad application market and development prospect in the blowdown pump series products.

Structure specification

1, the impeller of the self-priming pump adopts double blade design to ensure the dynamic balance of the rotor part and make the bearing more durable;

2, self-priming pump supporting motor insulation class B and F, protection class IP44 and 54 (for customers to choose) S1 continuous working system;

3. The bearing oil chamber of the self-priming pump is provided with a refueling hole, and the oil chamber of the general pump has been filled with butter when it leaves the factory, and butter should be added for a certain period of work;

4, the vertical height of self-priming is not more than 4.5~5.5 meters, the pump's self-pipet road can not exceed 10 meters, and there can be no siphon phenomenon during installation.

5, the diameter of the self-priming pump can pass the particle is generally about 40% of the diameter of the self-priming pump.

Note: When abnormal sound occurs in the self-priming pump, the cause of the abnormal sound should be identified, and the fault should be removed before starting up and running to ensure the safety of the self-priming pump.

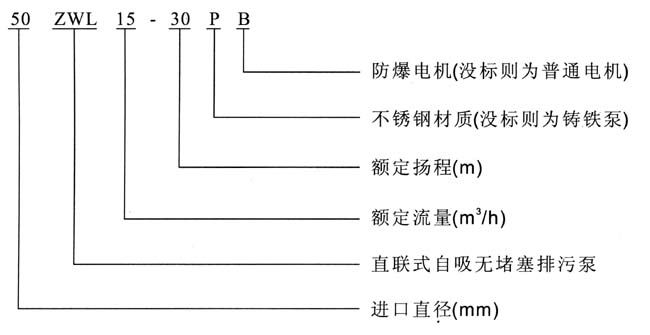

Type description

Working condition

1. ZWL (P) series self-priming pump is applicable when the rated voltage is 380V and the power frequency is 50Hz

2, medium temperature does not exceed 99 degrees Celsius, medium density ≤1150kg/m3,PH value in the range of 5-9;

3, the altitude does not exceed 1000 meters;

4, the annual viscosity of the conveying medium is not more than 1000CP;

5, the product material is mainly cast iron, can not be used in strong corrosive or containing strong corrosive media;

6, the product material is mainly stainless steel, ordering should be informed of the physical and chemical properties of the conveying medium, can not be transported in highly corrosive or containing highly corrosive media;

Performance parameter |

|

Flow range: ≤800m3/h |

Lift range: ≤80m |

Power range: ≤55kw |

Supporting motor: Y2, Y2B three-phase asynchronous motor |

Motor cooling: air cooling |

Medium temperature: -40℃ ~ 200℃ |

Ambient temperature: ≤40℃ |

Working pressure: ≤l.6 MP a |

Self-priming height: 2.5 ~ 7 m |

Self-priming time: ≤120S |

Working voltage :380V±5% (can be customized) |

Rated frequency: 50HZ (can be customized) |

Structural feature |

|

Installation form: horizontal self-priming |

Pump body structure: horizontal direct connection |

Impeller form: closed single suction |

Number of impeller: 1 |

Seal form: mechanical seal |

|

Main material |

|

Shaft bearing: rolling bearing |

Shaft sleeve material: cast iron, stainless steel |

Flow material: cast iron, stainless steel |

Outlet diameter: φ25mm-φ300mm |

Inlet diameter: φ25mm-φ300mm |

Pump shaft material: 45#, stainless steel |

Impeller material: cast iron, stainless steel |

|

Type parameter

Model number |

Flow rate m3/h |

head m |

power kw |

Rotational speed r/min |

efficiency % |

Cavitation allowance m |

Imbibition height m |

Imbibition time min/m |

Weight kg |

ZWL25-8-15 |

8 |

15 |

1.5 |

2900 |

45 |

2.0 |

5.0 |

3 |

68 |

ZWL32-9-30 |

9 |

30 |

3 |

2900 |

48 |

2.5 |

5.0 |

3 |

68 |

ZWL40-10-20 |

10 |

20 |

2.2 |

2900 |

45 |

2.5 |

5.0 |

3 |

95 |

ZWL40-20-15 |

20 |

15 |

2.2 |

2900 |

45 |

2.5 |

5.0 |

3 |

68 |

ZWL40-15-30 |

15 |

30 |

3 |

2900 |

48 |

2.5 |

5.0 |

3 |

68 |

ZWL50-10-20 |

10 |

20 |

2.2 |

2900 |

45 |

2.5 |

5.0 |

3 |

68 |

ZWL50-20-15 |

20 |

15 |

2.2 |

2900 |

45 |

2.5 |

5.0 |

3 |

68 |

ZWL50-15-30 |

15 |

30 |

3 |

2900 |

48 |

2.5 |

5.0 |

3 |

95 |

ZWL50-20-35 |

20 |

35 |

5.5 |

2900 |

48 |

2.5 |

5.5 |

3 |

140 |

ZWL50-20-40 |

20 |

40 |

7.5 |

2900 |

48 |

2.5 |

5.5 |

3 |

150 |

ZWL65-30-18 |

30 |

18 |

4 |

2900 |

45 |

2.5 |

5.0 |

3 |

125 |

ZWL65-25-30 |

25 |

30 |

5.5 |

2900 |

50 |

3.0 |

5.0 |

3 |

135 |

ZWL65-25-40 |

25 |

40 |

7.5 |

2900 |

50 |

3.0 |

5.5 |

2 |

140 |

ZWL65-40-25 |

40 |

25 |

7.5 |

2900 |

50 |

3.0 |

5.0 |

3 |

150 |

ZWL65-65-25 |

65 |

25 |

11 |

2900 |

52 |

3.0 |

5.0 |

3 |

200 |

ZWL80-40-16 |

40 |

16 |

4 |

2900 |

50 |

3.0 |

5.0 |

3 |

125 |

ZWL80-40-25 |

40 |

25 |

7.5 |

2900 |

50 |

3.0 |

5.0 |

3 |

140 |

ZWL80-25-40 |

25 |

40 |

7.5 |

2900 |

50 |

3.0 |

5.5 |

2 |

150 |

ZWL80-65-25 |

65 |

25 |

11 |

2900 |

52 |

3.0 |

5.0 |

3 |

220 |

ZWL80-80-35 |

80 |

35 |

15 |

2900 |

45 |

3.0 |

5.5 |

3 |

250 |

ZWL80-50-60 |

50 |

60 |

22 |

2900 |

55 |

3.0 |

5.5 |

3 |

300 |

ZWL100-100-15 |

100 |

15 |

7.5 |

1450 |

50 |

4.0 |

5.0 |

3 |

230 |

ZWL100-80-20 |

80 |

20 |

7.5 |

1450 |

53 |

4.0 |

5.0 |

3 |

230 |

ZWL100-100-20 |

100 |

20 |

11 |

1450 |

53 |

4.0 |

5.0 |

3 |

270 |

ZWL100-100-30 |

100 |

30 |

22 |

1450 |

53 |

4.0 |

5.0 |

2 |

320 |

ZWL100-80-45 |

80 |

45 |

30 |

2900 |

53 |

4.0 |

5.5 |

2 |

380 |

ZWL100-80-60 |

80 |

60 |

37 |

2900 |

53 |

4.0 |

5.5 |

2 |

430 |

ZWL100-80-80 |

80 |

80 |

45 |

2900 |

53 |

4.0 |

5.5 |

2 |

480 |

ZWL125-120-20 |

120 |

20 |

15 |

1450 |

55 |

4.5 |

5.0 |

2 |

380 |

ZWL150-200-15 |

200 |

15 |

15 |

1450 |

60 |

5.0 |

5.0 |

3.5 |

380 |

ZWL150-200-20 |

200 |

20 |

22 |

1450 |

60 |

5.0 |

5.0 |

3 |

420 |

ZWL150-200-25 |

200 |

25 |

30 |

1450 |

60 |

5.0 |

5.0 |

3 |

520 |

ZWL150-180-30 |

180 |

30 |

37 |

1450 |

65 |

5.0 |

5.0 |

3 |

580 |

ZWL150-180-38 |

180 |

38 |

55 |

1450 |

45 |

5.0 |

5.0 |

3.5 |

700 |

ZWL200-280-14 |

280 |

14 |

22 |

1450 |

65 |

5.0 |

5.0 |

3 |

600 |

ZWL200-300-18 |

300 |

18 |

37 |

1450 |

65 |

5.0 |

5.0 |

3 |

680 |

ZWL200-280-28 |

280 |

28 |

55 |

1450 |

55 |

4.8 |

5.2 |

3 |

820 |

ZWL250-420-20 |

420 |

20 |

55 |

1450 |

61 |

6.0 |

4.5 |

2.5 |

1020 |

ZWL300-800-14 |

800 |

14 |

55 |

1450 |

65 |

6.0 |

4.5 |

2.5 |

1200 |